Analysis of Sweep Volume Effect on the Output Power and Velocity of a Gamma-Type Stirling Engine with Slider-Crank Mechanism Features

DOI:

https://doi.org/10.22034/advjscieng21022103Keywords:

Numerical analysis, Output power, Stirling engine, Slider-crank mechanismAbstract

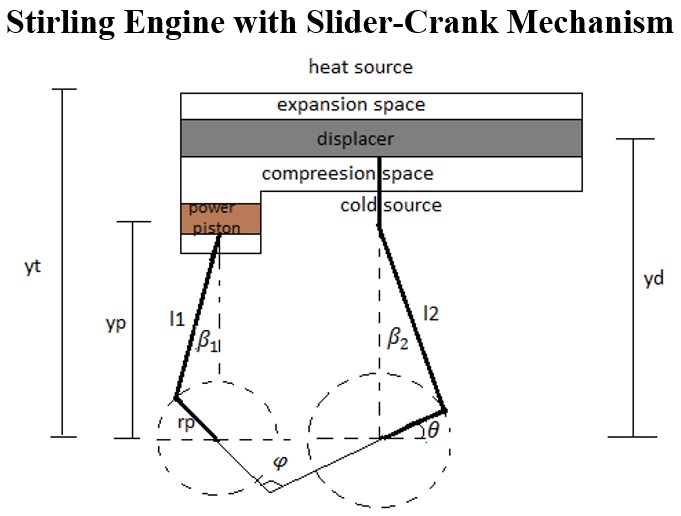

The Stirling engine is an external combustion engine that can generate electricity without any pollution; in the other words, it can generate energy from renewable energy sources such as solar energy. In this research, the gamma-type Stirling engine with slider-crank mechanism with three different sweep volume ratios 1, 1.5, and 2 are manufactured and compared. It is observed that in the engine when the sweep volume ratio is 2, the result is better and more than the remaining types; Another conclusion from this comparison is that a lower temperature difference is required for a larger sweep volume ratio. So, the engine when the sweep volume ratio is 2, a lower temperature difference required for reaching a higher and better output is required.

References

Vyas N, Patel M, Makwana K. Design and manufacturing of solar Stirling engine. B.Sc. Thesis, Patel College of Engineering, Ganpat University: Kherva. 2013.

Corria ME, Cobas VM, Lora ES. Perspectives of Stirling engines use for distributed generation in Brazil. Energy Policy. 2006;34:3402-3408.

Kongtragool B, Wongwises S. A review of solar-powered Stirling engines and low temperature differential Stirling engines. Renewable and Sustainable Energy Reviews. 2003;7:131-154.

Vineeth CS. Stirling engine: a beginners guide. Department of Mechanical Engineering, College of Engineering Thiruvananthapuram. 2012.

Marra FS, Miccio F, Solimene R, Chirone R, Urciuolo M, Miccio M. Coupling a Stirling engine with a fluidized bed combustor for biomass. International Journal of Energy Research. 2020;44:12572-12582.

Miccio F. On the integration between fluidized bed and Stirling engine for micro-generation. Applied Thermal Engineering. 2013;52:46-53.

Ding G, Huang S, Zhang C, Hu X, Zhang X. A study on design parameters of stirling engines for buildings. Ding G, Huang S, Zhang C, Hu X, Zhang X. A study on design parameters of Stirling engines for buildings. Renewable Energy Resources and a Greener Future. 2006.

Walker G, Fauvel OR, Reader G. The literature of Stirling engines. Proceedings of the 24th Intersociety Energy Conversion Engineering Conference. 1989:2337-2340.

Foster PR. Innovative rotary displacer Stirling engine: Sustainable power generation for private and fleet vehicle applications. The Journal of Technology Studies. 2011;37:95-107

Thombare DG, Verma SK. Technological development in the Stirling cycle engines. Renewable and Sustainable Energy Reviews. 2008;12:1-38.

Timoumi Y, Tlili I, Nasrallah SB. Performance optimization of Stirling engines. Renewable energy. 2008 ;33:2134-2144.

Kongtragool B, Wongwises S. Performance of -temperature differential Stirling engines. Renewable Energy. 2007;32:547-566.

Cinar C, Karabulut H. Manufacturing and testing of a gamma type Stirling engine. Renewable energy. 2005 Jan 1;30(1):57-66.

Cheng CH, Yang HS. Optimization of geometrical parameters for Stirling engines based on theoretical analysis. Applied Energy. 2012;92:395-405.

Boutammachte N, Knorr J. Field-test of a solar low delta-T Stirling engine. Solar Energy. 2012;86:1849-1856.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Advanced Journal of Science and Engineering

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License (CC-BY 4.0).