Comparing Effects of Different Nanoparticles and Compatibilizers on the Properties of Thermoplastic Polyester Elastomer Nanocomposites

DOI:

https://doi.org/10.22034/advjscieng21022086Keywords:

Thermoplastic polyester elastomer, Nano-TiO2, Nano-ZnO, Nanocomposite, Morphology, Mechanical propertiesAbstract

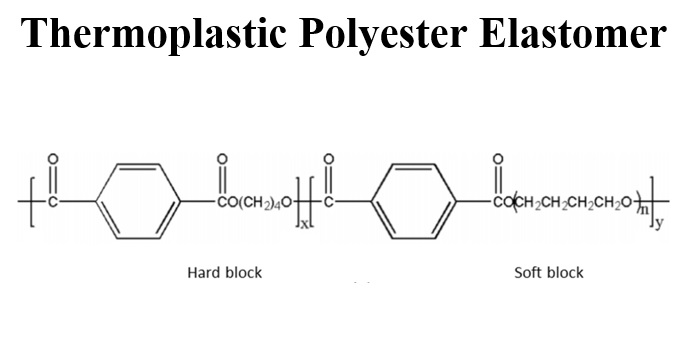

Reinforced polymer flexible composites, including nanoparticles (titan dioxide, nTiO2, and Zinc oxide, ZnO), reveal new avenues of engineering that demonstrate better mechanical and chemical features. This paper examines the effects of nanoparticles and compatibilizers (maleated styrene-(ethylene-co-butylene)-styrene, SEBSMA and stearic acid, SA) on the features of poly(butylene terephthalate)-block-tetramethylene ether glycol terephthalate (PBT-TEGT)-based thermoplastic polyester elastomer (TPE). The nanoparticle content in the matrix was varied from 1 to 5 wt%. The surface of the nanoparticles was modified with different compatibilizers such as SA and SEBSMA before melt blending for better surface adhesion and fine dispersion. The effects of modified and unmodified nanoparticles with a varying concentration on the morphological and mechanical features of TPE/nanoparticles nanocomposites were manufactured by a twin-screw extruder followed by a heat press machine. Due to the stiff structure of nanoparticles, all tensile features (yield strength, tensile strength, and tensile modulus) increased while impact strength and elongation at break reduced. Consequently, although nTiO2 has a higher hardness than nZnO, the elongation of nanocomposites with nTiO2 was higher than that of nZnO. The presence of SA in TPE/nTiO2 nanocomposite was more effective than the presence of SEBSMA in TPE/nTiO2 nanocomposite. On the contrary, the tensile features of SA modified nTiO2 nanocomposites were higher than that of SA modified nZnO nanocomposite. This is probably due to the better compatibility of nTiO2 with SA and in this case, the more fine structure of nTiO2 with TPE has been induced, which ensures the result of lower elongation at break.

References

Jiang R, Chen Y, Yao S, Liu T, Xu Z, Park CB, Zhao L. Preparation and characterization of high melt strength thermoplastic polyester elastomer with different topological structure using a two-step functional group reaction. Polymer. 2019;179:121628.

Kalfoglou NK. Thermomechanical studies of semicrystalline polyether–ester copolymers. Effect of thermal, mechanical, and solvent treatment. Journal of Applied Polymer Science. 1977;21:543-554.

Yao C, Yang G. Crystallization, and morphology of poly (trimethylene terephthalate)/poly (ethylene oxide terephthalate) segmented block copolymers. Polymer. 2010;51:1516-1523.

Hashimoto M, Takadama H, Mizuno M, Kokubo T. Mechanical properties and apatite forming ability of TiO2 nanoparticles/high density polyethylene composite: effect of filler content. Journal of Materials Science. 2007;18:661-668.

Kruenate J, Tongpool R, Panyathanmaporn T, Kongrat P. Optical and mechanical properties of polypropylene modified by metal oxides. Surface and Interface Analysis. 2004;36:1044-1047.

Rong MZ, Zhang MQ, Zheng YX, Zeng HM, Friedrich K. Improvement of tensile properties of nano-SiO2/PP composites in relation to percolation mechanism. Polymer. 2001;42:3301-3304.

Maiti S, Lopez B. Tensile properties of polypropylene/kaolin composites. Journal of Applied Polymer Science. 1992;44:353-360.

Wang Z, Lu Y, Liu J, Dang Z, Zhang L, Wang W. Preparation of nano?zinc oxide/EPDM composites with both good thermal conductivity and mechanical properties. Journal of Applied Polymer Science. 2011;119:1144-1155.

Altan M, Yildirim H. Mechanical and antibacterial properties of injection molded polypropylene/TiO2 nano-composites: Effects of surface modification. Journal of Materials Science & Technology. 2012;28:686-692.

Huang C, Chen S, Wei W. Processing and property improvement of polymeric composites with added ZnO nanoparticles through microinjection molding. Journal of Applied Polymer Science. 2006;102:6009-6016.

Tjong SC, Xu S-A, Li RK-Y, Mai Y-W. Mechanical behavior and fracture toughness evaluation of maleic anhydride compatibilized short glass fiber/SEBS/polypropylene hybrid composites. Composites Science and Technology. 2002;62:831-840.

Ishida H, Campbell S, Blackwell J. General approach to nanocomposite preparation. Chemistry of Materials. 2000;12:1260-1267.

Rahman M, Hoque MA, Rahman G, Gafur M, Khan RA, Hossain MK. Study on the mechanical, electrical and optical properties of metal-oxide nanoparticles dispersed unsaturated polyester resin nanocomposites. Results in Physics. 2019;13:102264.

Zaman HU, Hun PD, Khan RA, Yoon K-B. Effect of surface-modified nanoparticles on the mechanical properties and crystallization behavior of PP/CaCO3 nanocomposites. Journal of Thermoplastic Composite Materials. 2013;26:1057-1070.

Ghazy O, Freisinger B, Lieberwith I, Landfester K. Tuning the size and morphology of P3HT/PCBM composite nanoparticles: towards optimized water-processable organic solar cells. Nanoscale. 2020;12:22798-22807.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Advanced Journal of Science and Engineering

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License (CC-BY 4.0).