Nanoparticle Concentration and Heat Treatment Effects on Microstructure and Tribological Behavior of the Ni-P Nanocomposite Coating

DOI:

https://doi.org/10.22034/advjscieng21022071Keywords:

Electroless Ni-P coating, Nanocomposite, Nanoparticle concentration, Wear resistanceAbstract

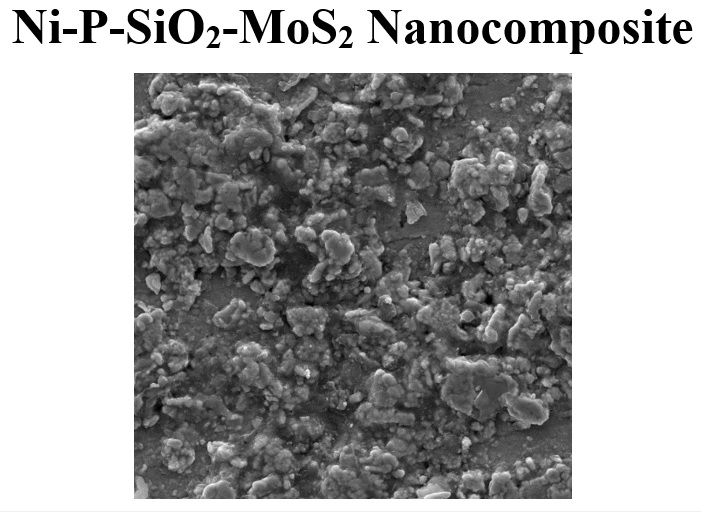

The aim of this study was to create electroless Ni-P-SiO2-MoS2 nanocomposite coating and investigate the effect of the concentration of nanoparticles and heat treatment on its structure and tribological behavior. To achieve this purpose, MO40 steel specimens were coated at the temperature of 90°C in electroless nickel-phosphorus coating baths containing different concentrations of 3, 7, 11, and 15 g/L of SiO2 and MoS2 reinforcement nanoparticles with pH 6.4 for 60 minutes. Then, the coated sample containing 7 g/L of nanoparticles was subjected to heat treatment of 400°C for 60 minute. To investigate the microstructure, tribological behavior, elements’ weight percent and phases in the coatings, FE-SEM images were observed and wear test, EDS and XRD analysis were performed, respectively. Results showed that by increasing the concentration of nanoparticles in the coating bath, the weight percent of the reinforcement elements in the coating increases. Exceeding concentration of nanoparticles from certain value leads to the agglomeration of the coating particles and creation of porosity which results in a non-uniform coating with low protecting properties. Therefore, the appropriate concentration of nanoparticles in the coating bath was chosen 7 g/L, because the results show a uniform coating of the amorphous nickel phase and the SiO2 and MoS2 nanoparticles. Subsequently, the heat treatment results showed that the amorphous nickel phase formed in the coating became into two crystalline nickel and Ni3P phases after heat treatment that leads to increase wear resistance.

References

Qin W. Microstructure and corrosion behavior of electroless Ni–P coatings on 6061 aluminum alloys. Journal of Coatings Technology and Research. 2011;8:135-139.

Liu X, Wu C, Wang X. Synthesis, characterization, and infrared-emissivity study of Ni–P–CB nanocomposite coatings by electroless process. Journal of Coatings Technology and Research. 2010;7:659-664.

Taha-Tijerina J, Aviña-Camarena K, Torres-Sánchez R, Dominguez-Ríos C, Maldonado-Cortes D. Tribological evaluation of electroless Ni–B coating on metal-working tool steel. The International Journal of Advanced Manufacturing Technology. 2019;103:1959-1964.

Banerjee T, Sen RS, Oraon B, Majumdar G. Predicting electroless Ni–Co–P coating using response surface method. The International Journal of Advanced Manufacturing Technology. 2013;64:1729-1736.

Carrillo DF, Santa AC, Valencia-Escobar A, Zapata A, Echeverría F, Gómez MA, Zuleta AA, Castaño JG. Tribological behavior of electroless Ni–P/Ni–P–TiO2 coatings obtained on AZ91D magnesium alloy by a chromium-free process. The International Journal of Advanced Manufacturing Technology. 2019;105:1745-1756.

Ji R, Liu Y, Xu C, Li X, Cai B, Zhang Y. Novel method for the hybrid composite electroplating of the upstream pumping mechanical seal. The International Journal of Advanced Manufacturing Technology. 2017;89:1875-1886.

Rezaee B, Rastegari S, Eyvazjamadi H. Formation mechanism of Pt-modified aluminide coating structure by out-of-the-pack aluminizing. Surface Engineering. 2021;37:343-350.

Mohammadi M, Ghorbani M, Azizi A. Effect of specimen orientation and heat treatment on electroless Ni-PTFE-MoS2 composite coatings. Journal of Coatings Technology and Research. 2010;7:697-702.

Palaniappa M, Seshadri SK. Friction and wear behavior of electroless Ni–P and Ni–W–P alloy coatings. Wear. 2008;265:735-740.

Liu YY, Yu J, Huang H, Xu BH, Liu XL, Gao Y, Dong XL. Synthesis and tribological behavior of electroless Ni–P–WC nanocomposite coatings. Surface and Coatings Technology. 2007;201:7246-7251.

Masoumi F, Ghasemi HR, Ziaei AA, Shahriari D. Tribological characterization of electroless Ni–10%P coatings at elevated test temperature under dry conditions. The International Journal of Advanced Manufacturing Technology. 2012;62:1063-1070.

Medelien V. The influence of B4C and SiC additions on the morphological, physical, chemical and corrosion properties of Ni coatings. Surface and Coatings Technology. 2002;154:104-111.

Bozzini B, Boniardi M, Fanigliulo A, Bogani F. Tribological properties of electroless Ni-P/diamond composite films. Materials Research Bulletin. 2001;36:1889-1902.

Rezaee B, Kermani E, Biniyazan F, Ejlali, S, Soleimanimehr H. Effect of SiO2 and MoS2 nanoparticles on microstructure and wear resistance of electroless nanocomposite Ni-P-SiO2-MoS2 coating. Iranian Journal of Manufacturing Engineering. 2020;7:65-71.

Sudagar J, Lian J, Sha W. Electroless nickel, alloy, composite and nano coatings–A critical review. Journal of Alloys and Compounds. 2013;571:183-204.

Hu X, Jiang P, Wan J, Xu Y, Sun X. Study of corrosion and friction reduction of electroless Ni–P coating with molybdenum disulfide nanoparticles. Journal of Coatings Technology and Research. 2009;6:275-281.

Sahoo P, Das SK. Tribology of electroless nickel coatings–a review. Materials & Design. 2011;32:1760-1775.

Keong KG, Sha W, Malinov S. Crystallization and phase transformation behaviour of electroless nickel-phosphorus deposits with low and medium phosphorus contents under continuous heating. Journal of Materials Science. 2002;37:4445-4450.

Biniyazan F, Soleimanimehr H. Improving both strength and ductility of Al-7075 by combining dual equal channel lateral extrusion with aging heat treatment. Iranian Journal of Science and Technology, Transactions of Mechanical Engineering. 2021; in press.

Agarwala RC, Agarwala V. Electroless alloy/composite coatings: A review. Sadhana. 2003;28:475-493.

Nishira M, Takano O. Friction and wear characteristics of electroless Ni-P-PFTE composite coatings. Plating and Surface Finishing. 1994;81:48-50.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Advanced Journal of Science and Engineering

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License (CC-BY 4.0).