Nafion-Based Ionic-Polymer-Metal Composites: Displacement Rate Analysis by Changing Electrode Properties

DOI:

https://doi.org/10.22034/advjscieng21021051Keywords:

IPMC, Displacement, Finite element, Electromechanical, Smart material compositeAbstract

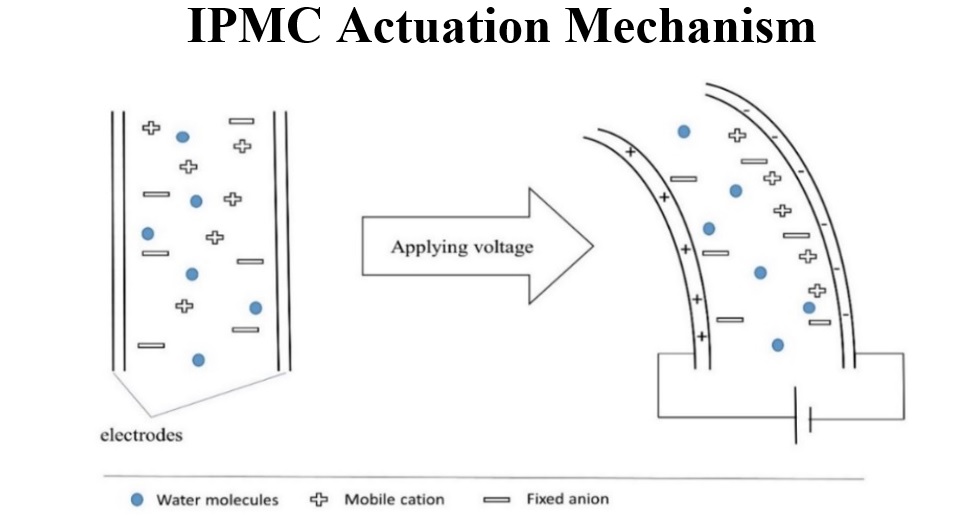

In this paper, a polymer-metal ion composite is modeled in two dimensions. The core material is Nafion 117 and the electromechanical effects of electrodes with four different materials of aluminum, gold, copper, and titanium on the stress and displacement are investigated by finite element method. Based on the properties of each material such as corrosion resistance, conductivity cost of metals and the results of the analysis, aluminum has the maximum displacement and copper is the most conductive metal but they oxidize quickly in contact of air or water. On the other hand, gold has excellent resistance to erosion and can be manufactured with very thin thickness. It has also been shown that titanium is not an optimal metal due to its scarcity and properties contrary to the needs of an efficient IPMC. Also, the stress created in the piece is almost equal in all four cases.

References

Soleimanimehr H, Mirzaei M, Ghani M, Sattari F, Najafabadi AF. Micro-grooving of aluminum, titanium and magnesium alloys by Acidithiobacillus ferrooxidans bacteria. Advanced Journal of Science and Engineering. 2020;1:16-19.

Soleimanimehr H. Analysis of the cutting ratio and investigating its influence on the workpiece’s diametrical error in ultrasonic-vibration assisted turning. Proceedings of the Institution of Mechanical Engineers B. 2021;235:640-649.

Punning A, Johanson U, Anton M, Kruusmaa M, Aabloo A. A distributed model of IPMC. Electroactive Polymer Actuators and Devices. 2008;6927:69270G.

Bhandari B, Lee GY, Ahn SH. A review on IPMC material as actuators and sensors: fabrications, characteristics and applications. International Journal of Precision Engineering and Manufacturing. 2012;13:141-163.

Shahinpoor M. Ionic polymer metal composites (IPMCs): smart multi-functional materials and artificial muscles. London: Cambridge. 2016.

Gad-el-Hak M. The MEMS handbook. CRC Press. 2001.

Judy JW. Microelectromechanical systems (MEMS): fabrication, design and applications. Smart Materials and Structures. 2001;10:1115-1134.

Kim B, Kim BM, Ryu J, Oh IH, Lee SK, Cha SE, Pak J. Analysis of mechanical characteristics of the ionic polymer metal composite (IPMC) actuator using cast ion-exchange film. Smart Structures and Materials. 2003;5051:486-495.

Soleimanimehr H, Hosseini Z, Habibi M, Goortani BM. Energy harvesting from wind by piezoelectric for autonomous remote sensor. Advanced Journal of Science and Engineering. 2020;1:80-85.

Soleimanimehr H, Javangoroh S, Nasrollah A. Finite element analysis of ion-polymer-metal composite valve with copper electrode. The 10th National Conference of Iran Association of Mechanical Engineering. 2020:1057.

Farinholt K. Modeling and characterization of ionic polymer transducers for sensing and actuation. Doctoral Dissertation at Virginia Polytechnic Institute and State University. 2005.

Chen Z, Tan X. A control-oriented and physics-based model for ionic polymer-metal composite actuators. IEEE/ASME Transactions on Mechatronics. 2008;13:519-529.

Nemat-Nasser S. Micromechanics of actuation of ionic polymer-metal composites. Journal of Applied Physics. 2002;92:2899-2915.

Lee S, Kim KJ, Park HC. Modeling of an IPMC actuator-driven zero-net-mass-flux pump for flow control. Journal of Intelligent Material Systems and Structures. 2006;17:533-541.

Patnaik S, Hopkins D. Strength of materials: a new unified theory for the 21st century. Butterworth-Heinemann. 2004.

Kundu S, Simon LC, Fowler M, Grot S. Mechanical properties of Nafion™ electrolyte membranes under hydrated conditions. Polymer. 2005;46:11707-11715.

Biniyazan F, Soleimanimehr H. Improving both strength and ductility of Al-7075 by combining dual equal channel lateral extrusion with aging heat treatment. Iranian Journal of Science and Technology, Transactions of Mechanical Engineering. 2021; 223:641-651.

Cardarelli F. Materials handbook. London: Springer. 2018.

Kiener D, Motz C, Schöberl T, Jenko M, Dehm G. Determination of mechanical properties of copper at the micron scale. Advanced Engineering Materials. 2006;8:1119-1125.

Greer JR, Oliver WC, Nix WD. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Materialia. 2005;53:1821-1830.

Sergueeva AV, Stolyarov VV, Valiev RZ, Mukherjee AK. Advanced mechanical properties of pure titanium with ultrafine grained structure. Scripta Materialia. 2001;45:747-752.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Advanced Journal of Science and Engineering

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License (CC-BY 4.0).