Friction Stir Welding of CuZn40 Brass Alloy based on Optimal Response Surface Results: Numerical and Experimental Analyses

DOI:

https://doi.org/10.22034/advjscieng21021003Keywords:

Friction stir welding, CuZn40 brass alloy, Temperature contour, Response surface method, Finite element analysisAbstract

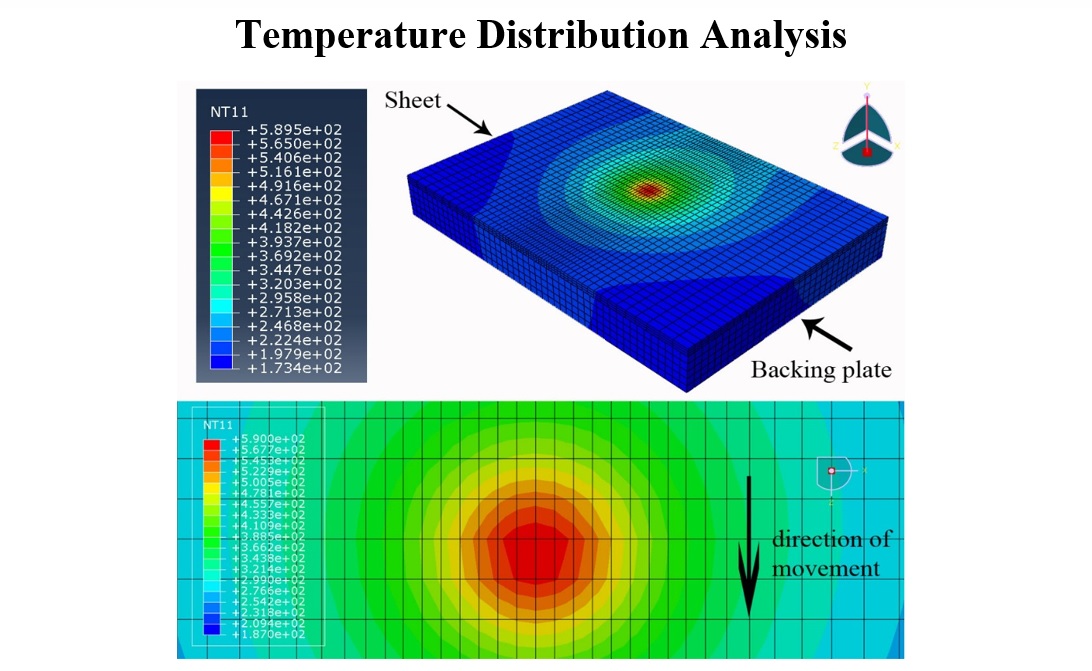

CuZn40 brass alloy with 38-42% zinc content has different applications regarding its formability and machinability properties. In this study, friction stir welding (FSW) of CuZn40 brass alloy was performed by selecting the specified welding parameters according to the design of experiment (DOE) table. Regarding to the response surface method (RSM) with central composite design (CCD), an optimization was done according to the results of the specimen tensile test and the final function related to it was extracted. In order to achieve a predictive finite element model, an attempt was first made to consider all simulation cases regarding the experimental test. Then, by calibrating the model, while placing the optimal parameters in it, the temperature results were compared in practical mode and simulation. Finally, the relationship between welding parameters and ultimate tensile strength was investigated.

References

Dabeer P, Shinde G. Perspective of friction stir welding tools. Materials Today: Proceedings. 2018;5:13166-13176.

Mandal S, Rice J, Elmustafa AA. Experimental and numerical investigation of the plunge stage in friction stir welding. Journal of Materials Processing Technology. 2008;203:411-419.

Shi L, Wu CS. Transient model of heat transfer and material flow at different stages of friction stir welding process. Journal of Manufacturing Processes. 2017;25:323-339.

Ghetiya ND, Patel KM, Patel AB. Prediction of temperature at weldline in air and immersed friction stir welding and its experimental validation. The International Journal of Advanced Manufacturing Technology. 2015;79:1239-1246.

He X, Gu F, Ball A. A review of numerical analysis of friction stir welding. Progress in Materials Science. 2014;65:1-66.

Nandan R, DebRoy T, Bhadeshia HK. Recent advances in friction-stir welding–process, weldment structure and properties. Progress in materials science. 2008 Aug 1;53:980-1023.

ASM. Properties and selection: nonferrous alloys and special-purpose materials. ASM: Cleveland, 1990

Farabi E, Zarei-Hanzaki A, Abedi HR. High temperature formability prediction of dual phase brass using phenomenological and physical constitutive models. Journal of Materials Engineering andPperformance. 2015;24:209-220.

Balík J, Faltus J, Jane?ek M. High temperature creep of modified ?+ ? brasses. Materials Science and Engineering A. 2008;494:113-121.

ASM. Welding, brazing, and soldering. ASM: Cleveland, 1993.

Hasan A. Studying the corrosion of brass weldments by weight losses method. Australian Journal of Basic and Applied Sciences. 2014;8:106-112.

Meran C, Yuksel M, Gulsoz A, Sekercioglu T. Welding problems with thin brass plates and tungsten inert gas pulse welding. Science and Technology of Welding and Joining. 2004;9:131-137.

Ramesh R, Dinaharan I, Akinlabi ET, Murugan N. Microstructure and mechanical characterization of friction-stir-welded dual-phase brass. Journal of Materials Engineering and Performance. 2018 Apr;27(4):1544-54.

Meran C. The joint properties of brass plates by friction stir welding. Materials & Design. 2006;27:719-726.

Zhou L, Zhou WL, Feng JC, He WX, Huang YX, Dong SS. Effect of rotation speed on the microstructure and mechanical properties of dissimilar friction stir-welded copper/brass metals. The International Journal of Advanced Manufacturing Technology. 2016;84:1335-1343.

Çam G, Mistikoglu S, Pakdil M. Microstructural and mechanical characterization of friction stir butt joint welded 63% Cu-37% Zn brass plate. Welding Journal. 2009;88:225-232.

Çam G, Serinda? HT, Çakan A, Mistikoglu S, Yavuz H. The effect of weld parameters on friction stir welding of brass plates. Materialwissenschaft und Werkstofftechnik: Entwicklung, Fertigung, Prüfung, Eigenschaften und Anwendungen technischer Werkstoffe. 2008;39:394-399.

Esmaeili A, Givi MB, Rajani HZ. A metallurgical and mechanical study on dissimilar friction stir welding of aluminum 1050 to brass (CuZn30). Materials Science and Engineering A. 2011;528:7093-7102.

Moghaddam MS, Parvizi R, Haddad-Sabzevar M, Davoodi A. Microstructural and mechanical properties of friction stir welded Cu–30Zn brass alloy at various feed speeds: influence of stir bands. Materials & Design. 2011;32:2749-2755.

Xu N, Ueji R, Fujii H. Enhanced mechanical properties of 70/30 brass joint by rapid cooling friction stir welding. Materials Science and Engineering A. 2014;610:132-138.

Sun YF, Xu N, Fujii H. The microstructure and mechanical properties of friction stir welded Cu–30Zn brass alloys. Materials Science and Engineering A. 2014;589:228-234.

Mironov S, Sato YS, Kokawa H. Development of grain structure during friction stir welding of pure titanium. Acta Materialia. 2009;57:4519-4528.

Shojaeefard MH, Khalkhali A, Akbari M, Tahani M. Application of Taguchi optimization technique in determining aluminum to brass friction stir welding parameters. Materials & Design. 2013;52:587-592.

Shojaeefard MH, Akbari M, Khalkhali A, Asadi P, Parivar AH. Optimization of microstructural and mechanical properties of friction stir welding using the cellular automaton and Taguchi method. Materials & Design. 2014;64:660-666.

Safeen W, Hussain S, Wasim A, Jahanzaib M, Aziz H, Abdalla H. Predicting the tensile strength, impact toughness, and hardness of friction stir-welded AA6061-T6 using response surface methodology. The International Journal of Advanced Manufacturing Technology. 2016;87:1765-1781.

Ghaffarpour M, Dariani BM, Hossein Kokabi A, Razani NA. Friction stir welding parameters optimization of heterogeneous tailored welded blank sheets of aluminium alloys 6061 and 5083 using response surface methodology. Proceedings of the Institution of Mechanical Engineers B. 2012;226:2013-2022.

Farzadi A, Bahmani M, Haghshenas DF. Optimization of operational parameters in friction stir welding of AA7075-T6 aluminum alloy using response surface method. Arabian Journal for Science and Engineering. 2017;42:4905-4916.

Heidarzadeh A. Tensile behavior, microstructure, and substructure of the friction stir welded 70/30 brass joints: RSM, EBSD, and TEM study. Archives of Civil and Mechanical Engineering. 2019;19:137-146.

Panda B, Garg A, Jian Z, Heidarzadeh A, Gao L. Characterization of the tensile properties of friction stir welded aluminum alloy on joints axial force, traverse speed, and rotational speed. Frontiers of Mechanical Engineering. 2016;11:289-298.

Ghangas G, Singhal S. Modelling and optimization of process parameters for friction stir welding of armor alloy using RSM and GRA-PCA approach. Materials Research Express. 2018;6:1-25.

Heidarzadeh A, Barenji RV, Esmaily M, Ilkhichi AR. Tensile properties of friction stir welds of AA 7020 aluminum alloy. Transactions of the Indian Institute of Metals. 2015;68:757-767.

Uyyuru RK, Kailas SV. Numerical analysis of friction stir welding process. Journal of Materials Engineering and Performance. 2006;15:505-518.

Bahemmat P, Haghpanahi M, Givi MK, Seighalani KR. Study on dissimilar friction stir butt welding of AA7075-O and AA2024-T4 considering the manufacturing limitation. The International Journal of Advanced Manufacturing Technology. 2012;59:939-953.

Salari E, Jahazi M, Khodabandeh A, Ghasemi-Nanesa H. Influence of tool geometry and rotational speed on mechanical properties and defect formation in friction stir lap welded 5456 aluminum alloy sheets. Materials & Design. 2014;58:381-389.

Xu W, Liu J, Zhu H, Fu L. Influence of welding parameters and tool pin profile on microstructure and mechanical properties along the thickness in a friction stir welded aluminum alloy. Materials & Design. 2013;47:599-606.

Emamikhah A, Abbasi A, Atefat A, Givi MB. Effect of tool pin profile on friction stir butt welding of high-zinc brass (CuZn40). The International Journal of Advanced Manufacturing Technology. 2014;71:81-90.

Standard test method for tension testing of metallic materials. ASTM E 8M annual book of ASTM standards. Part 8; ASTM, 1998.

ProCast software. Version 2018.

Darvazi AR, Iranmanesh M. Thermal modeling of friction stir welding of stainless steel 304L. The International Journal of Advanced Manufacturing Technology. 2014;75:1299-1307.

Nandan RG, Roy GG, Lienert TJ, Debroy T. Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Materialia. 2007;55:883-895.

Goldak J, Chakravarti A, Bibby M. A new finite element model for welding heat sources. Metallurgical Transactions B. 1984;15:299-305.

Schmidt H, Hattel J, Wert J. An analytical model for the heat generation in friction stir welding. Modelling and Simulation in Materials Science and Engineering. 2003;12:143-157.

?ur?anovi? MB, Mijajlovi? MM, Mil?i? DS, Stamenkovi? DS. Heat generation during friction stir welding process. Tribology Industry. 2009;31:8-14.

Aval HJ, Serajzadeh S, Kokabi AH. Evolution of microstructures and mechanical properties in similar and dissimilar friction stir welding of AA5086 and AA6061. Materials Science and Engineering A. 2011;528:8071-8083.

Yaduwanshi DK, Bag S, Pal S. Heat transfer analyses in friction stir welding of aluminium alloy. Proceedings of the Institution of Mechanical Engineers B. 2015;229:1722-1733.

Ebrahimpour A, Mostafapour A, Bouzary H, Salahi S. Experimental Measurement and numerical simulation of temperature distribution and thermal history during friction stir welding of pure copper joints. Journal of Mechatronics. 2014;2:113-118.

Velaga SK, Ravisankar A. Finite element based parametric study on the characterization of weld process moving heat source parameters in austenitic stainless steel. International Journal of Pressure Vessels and Piping. 2017;157:63-73.

Montgomery DC. Design and analysis of experiments. John Wiley & Sons: 8th Ed., 2012.

Song M, Kovacevic R. Thermal modeling of friction stir welding in a moving coordinate system and its validation. International Journal of Machine Tools and Manufacture. 2003;43:605-615.

Chansoria P, Solanki P, Dasgupta MS. Parametric study of transient temperature distribution in FSW of 304L stainless steel. The International Journal of Advanced Manufacturing Technology. 2015;80:1223-1239.

GM X, Geng L. Effects of friction stir welding parameters on microstructures and mechanical properties of brass joints. Materials Transactions. 2008;79:1698-1701.

Chen J, Fujii H, Sun Y, Morisada Y, Kondoh K, Hashimoto K. Effect of grain size on the microstructure and mechanical properties of friction stir welded non-combustive magnesium alloys. Materials Science and Engineering A. 2012;549:176-184.

Hall EO. The Hall-Petch relationship. Proceedings of the Physical Society B. 1951;64:747-753.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Advanced Journal of Science and Engineering

This work is licensed under a Creative Commons Attribution 4.0 International License.

This work is licensed under a Creative Commons Attribution 4.0 International License (CC-BY 4.0).